Exploring the Relevance of Welding Evaluation in Industrial Applications: Guarding Against Failures and Enhancing Longevity

Welding assessment serves as an important line of defense in industrial applications, guaranteeing the architectural honesty and dependability of bonded parts. By systematically identifying problems such as porosity and insufficient blend, assessments not only stop failures however additionally extend the life-span of vital properties.

Role of Welding Assessment

Welding evaluation works as a crucial secure in commercial applications, making certain that bonded structures fulfill defined requirements of high quality and security. This process involves an organized examination of welds to verify their integrity, stamina, and compliance with recognized codes and specs. The function of welding examination is complex, encompassing both visual evaluations and non-destructive screening techniques, which may consist of ultrasonic, radiographic, or magnetic bit testing.

Furthermore, welding evaluation plays an essential role in regulative conformity. Eventually, the function of welding examination is vital in promoting safety, enhancing performance, and securing investments in commercial infrastructure.

Usual Welding Defects

One of the most widespread defects is porosity, defined by little gas pockets caught within the weld steel. This occurs as a result of pollutants or incorrect shielding gas, compromising the weld's strength. An additional substantial defect is insufficient fusion, where the weld steel fails to bond correctly with the base material, possibly bring about architectural weaknesses.

Splits can likewise create throughout or after the welding procedure, typically credited to thermal stresses or inappropriate air conditioning prices. In addition, undercutting, where the base steel is worn down along the weld grain, can compromise the joint and is frequently triggered by excessive heat input or incorrect strategy.

In addition, lack of penetration occurs when the weld steel does not get to the origin of the joint, leading to inadequate toughness. Understanding these usual problems is important for welders and assessors alike to make sure that welded structures fulfill safety and performance criteria, inevitably preventing potential failures in industrial applications.

Advantages of Normal Inspections

Regular evaluations serve as a crucial secure in making certain the integrity and longevity of welded structures. These examinations determine prospective issues and weaknesses that may endanger the integrity of welds, permitting timely removal prior to problems escalate. By implementing an organized examination regimen, companies can considerably reduce the threat of devastating failings that might result in pricey downtime, tools substitute, and even mishaps.

In addition, normal assessments contribute to improved quality assurance throughout the welding process. By adhering to a regular inspection schedule, business can ensure that their welding techniques fulfill well-known quality criteria and finest techniques. This not only cultivates a society of responsibility but also motivates continuous improvement among welding employees.

In addition, normal examinations facilitate better upkeep preparation. By recognizing damage early, companies can purposefully set up repair services and substitutes, minimizing disruption to operations. This aggressive strategy ultimately results in extensive asset life-span and boosted overall efficiency.

Last but not least, a commitment to normal her response assessments can improve a business's track record in the market. Customers and stakeholders increasingly value organizations that prioritize safety and high quality, thus boosting count on and potentially leading to increased service opportunities.

Market Criteria and Laws

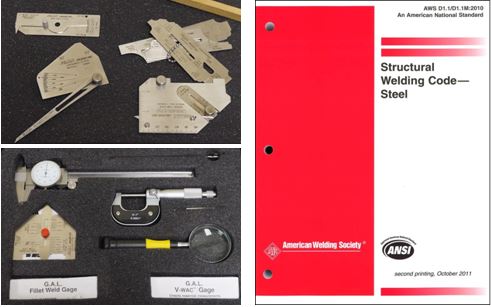

Following market criteria and regulations is a fundamental aspect of welding examination that matches the advantages of regular evaluations. These requirements, developed by companies such as the American Welding Culture (AWS) and the American Society of Mechanical Designers (ASME), supply a structure for finest techniques in welding processes, products, and examination techniques. Conformity with these guidelines ensures that welds satisfy the called for quality and safety benchmarks, dramatically decreasing the threat of architectural failings.

Governing bodies like the Occupational Safety and Wellness Management (OSHA) further apply guidelines that shield workers and the setting during welding procedures. By complying with these established requirements, sectors can enhance the reliability of their parts and frameworks, guaranteeing they carry out as intended under different functional conditions.

Additionally, adherence to market criteria fosters consistency in high quality control, facilitating smoother communication amongst stakeholders and regulatory companies. This placement not only lessens obligation threats however likewise improves the trustworthiness of organizations in competitive markets. Inevitably, compliance with welding standards and laws is not just a legal responsibility; it is an important financial investment in safety, efficiency, and long-lasting functional success.

Future Trends in Welding Inspection

As markets remain to evolve, the future of welding inspection is poised to integrate innovative modern technologies visit their website that enhance precision and performance. Among the most significant fads is the adoption of automation and robotics in examination processes. Automated systems can conduct examinations rapidly, minimizing human mistake and boosting throughput in producing atmospheres.

Furthermore, the combination of artificial intelligence (AI) and maker discovering algorithms will allow predictive analytics, enabling real-time evaluations and proactive upkeep (Welding Inspection Gilbert Arizona). By analyzing information from previous assessments, these technologies can determine patterns that can indicate potential failures, thus expanding the life-span of welded parts

Furthermore, the pattern in the direction of digitalization will lead to enhanced information helpful site management systems that help with far better tracking, reporting, and conformity with industry requirements. In recap, the future of welding examination is identified by technological improvements that assure to dramatically boost integrity, safety, and functional performance in different industrial applications.

Final Thought

In verdict, welding assessment offers a vital feature in ensuring the honesty and resilience of welded structures throughout various industrial applications. As advancements in innovation continue to develop, the future of welding evaluation promises enhanced precision and performance, inevitably adding to the longevity of important facilities.

Welding evaluation offers as a vital line of protection in industrial applications, making certain the structural integrity and dependability of welded elements.Welding examination serves as an important guard in commercial applications, guaranteeing that bonded frameworks meet defined standards of quality and safety - Welding Inspection Gilbert Arizona. Inevitably, the function of welding inspection is crucial in promoting safety, boosting performance, and securing financial investments in industrial infrastructure

These standards, developed by companies such as the American Welding Society (AWS) and the American Culture of Mechanical Engineers (ASME), offer a framework for finest methods in welding processes, materials, and inspection techniques.In conclusion, welding inspection serves an important function in ensuring the honesty and resilience of welded frameworks across different commercial applications.